roll forming machine design pdf

Performance test of three roll metal bending machine shaft design. Ad Decrease tooling cost and lead times with Quintus metal forming presses.

Corrugated Tile Roll Forming Machine Roof Panels Corrugated Metal Roof Roll Forming

Uboard Coyote Motorsports is a custom kart manufacturer and full-service machine manufacturing nearly everyponent on our popular line of go-karts with a Coyote Motorsports is an original American kart racing chassis manufacturer.

. Ad Shop Metalworking at MSC. Roll forming equipment Roll former machine technology downloads. Deformation during forming as well as the number of forming steps.

Quietest machine in the industry Eight forming stations for all roll sets - no opening roll on any roll set Large heavy duty bearings with inner races and grease fittings protect roll shafts and extend bearing life of the machine Slide out shaft design allows for easy maintenance Heavy duty 1 diameter stress proof roller. The machine h as six roller. What is a roll forming process.

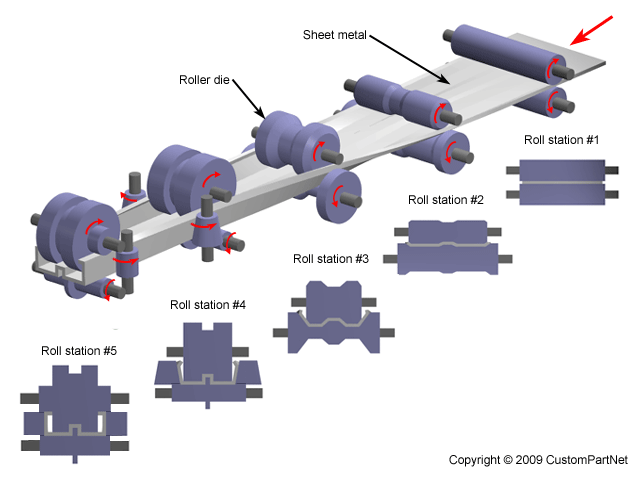

Ad Quality Roll Forming Machinery with Competitive Price. Continuous Rollforming is a bending operation where a long strip of sheet metal passes through multiple sets of rolls each set performing only an incremental part of the bend until the desired profile is obtained. About Roll Forming machine Design A Collection of rolls design according to the forming process roll flower design and adapt to form the steel sheet gradually.

How to Design for Roll Forming IN THIS VIDEO YOU GET MORE INFORMATION ABOUTroll forming machine design roll forming roller design Make roll forming machin. ROLL BENDING Roll forming roll bending or plate rolling is a continuous bending operation in which a long strip of metal typically coiled steel is passed through consecutive sets of rolls or stands each performing only an incremental part of the bend until the desired cross-section profile is obtained. In recent years it has also become possible to use finite element analysis for the design of roll forming processes.

PROFIL is the roll design software for every manufacturer of cold roll-formed profiles or seamed tubes from sheet metal and for designers of rollformers and tube forming machines. Increase your capacity by up to 80 with Quintus high pressure metal forming. The main purposes of this research are to construct a three roll metal bending machine and to do the performance tests.

ASC Manufacturers Complete Custom Purlin RollForming Lines. Next important elements are the structural dimensi ons of the existing roll forming machine. 1 day ago We design test and build custom kart racing frames.

The primary objective of the project is to design the transmission system of a rol forming machine using planetary gears. All Marketing Finances Sales. Roll Forming Machine is a processing machine that passes rolled steel or other long strips of metal through a series of Hardened Steel Rollers which are controlled using a pre-set PLC code to achieve a specific processing operation on the sheet metal at each station to produce a specific metal partIt is characterised by high progress high speed low scrap and one-off forming.

To meet your specific needs we always try to find the best. Ad Innovative design - Highest level of Flexibility in the purlin market worldwide. The objective of the work presented in this thesis was to answer the fol-lowing question.

Superda Successful to pass CE testing on AugustRoll former CE report issue by Italy company. The are many types of roll forming machines. Long production line with more than twenty stands of rolls causes the forming defects of the twisting and the bowling and the swinging and the wrinkling and the spring back of the.

In this research shaft. Rollforming is capable of forming more than just cylinders. No228 Yongli Nanyang Street Xiaoshan District Hangzhou City Zhejiang P.

How should the roll forming process be designed for complex geometries. The aim of this project is to develop a portable metal bending machine to bend sheet into curves and the other curvature shapes. Roll former CE Report.

Dimensions scheme of the existing machine before. We ROLL FORMING CO Ltd are specialized in the design development and manufacture of wide range of sheet metal coil processing equipment which includes but not limited to roll forming machine line tube mill line with high frequency welding system. Get Access to an Online Library of 85k Forms Packages that You Can Edit eSign Online.

SELECTION OF GEAR BOX FOR THE OPERATION The gear design is the most essential part of the entire in the entire design process. PROFIL enables quicker working and cost reductions in planning design calculation and drawing of the profile the flower pattern bending steps and the roll tooling. Get In Touch Today.

Trusted China Suppliers Verified by SGS. Find Industry-specific Forms Now. Ad Sign Fill Out Legal Forms Online on Any Device.

Get What You Need When You Need It. It also channels and U-bends. The gear design was completed in following stages.

Roll Forming Machine Roll Forming Machine Manufacturers

Metal Enclosure Roll Forming Machine For Producing Electrical Box

Export To Peru Roll Forming Machine Making Electrical Enclosure

Sheet Forming Process An Overview Sciencedirect Topics

D Tube Roll Forming Machine Making Machine Roll Forming Whole Brain Teaching

Din Rail Roll Forming Machine Price

Pin On Construction Material Roll Forming Machine

Steel Roll Forming Machine Roll Forming Wall Boxes Machine Service

Rolling Mills 6 Different Types Of Rolling Mills Images Pdf

Sheet Metal Materials Standard Sizes Forming Processes

Roofing Wall Galvanized Corrugated Tile Profiles Roll Forming Machine Roll Forming Galvanized Corrugated

How To Design For Roll Forming Roll Forming Software Roll Forming Design

Roll Forming Machine Suppliers For Metal Purlin Forming Electronic Enclosure Roll Former Design Solution Roll Forming Metal Forming Making Machine

Cable Tray Roll Forming Machine Factory Cable Tray Roll Forming Tray

We Can Design And Manufacture Roll Forming Machine According To The Customer S Request With Faster Time And Better Service Ht Cold Rolled Roll Forming Cold

The Function Of Color Plate Cold Roll Forming Machine Roll Forming Cylinder Cold Rolled

Roll Forming Machine Design Roll Former Design Believe Industry